summarize

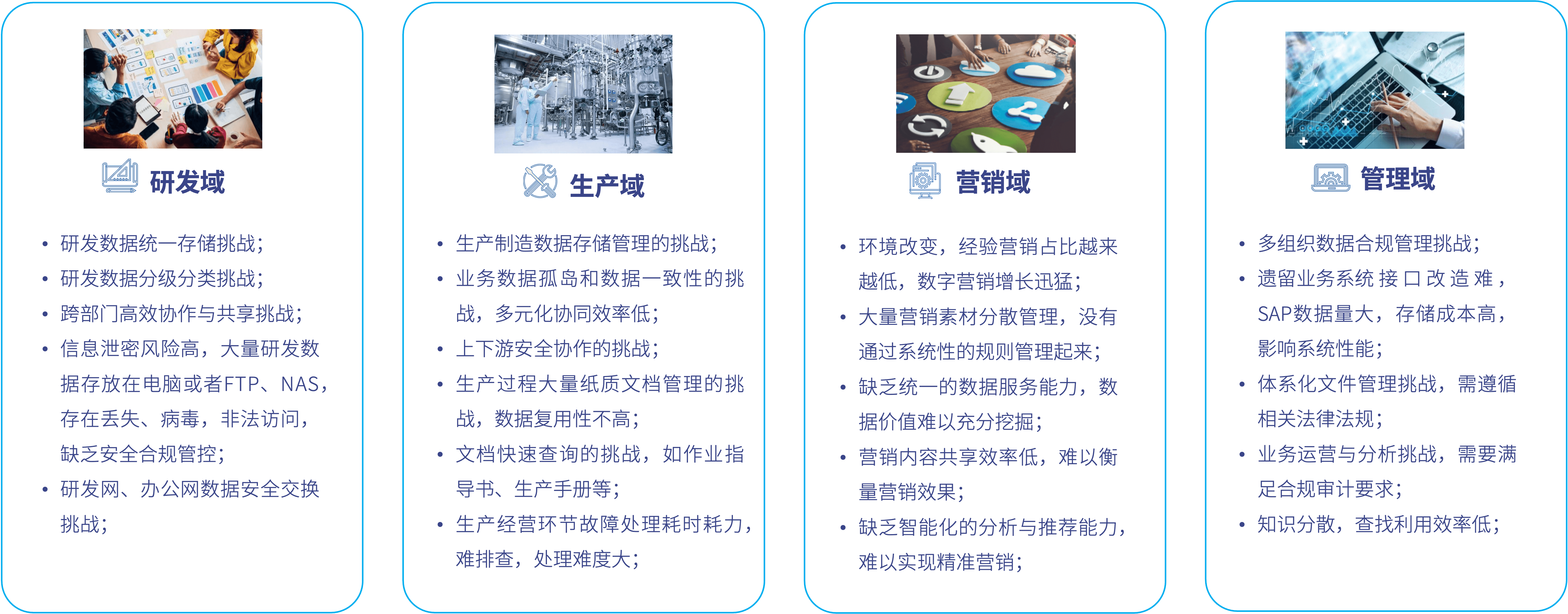

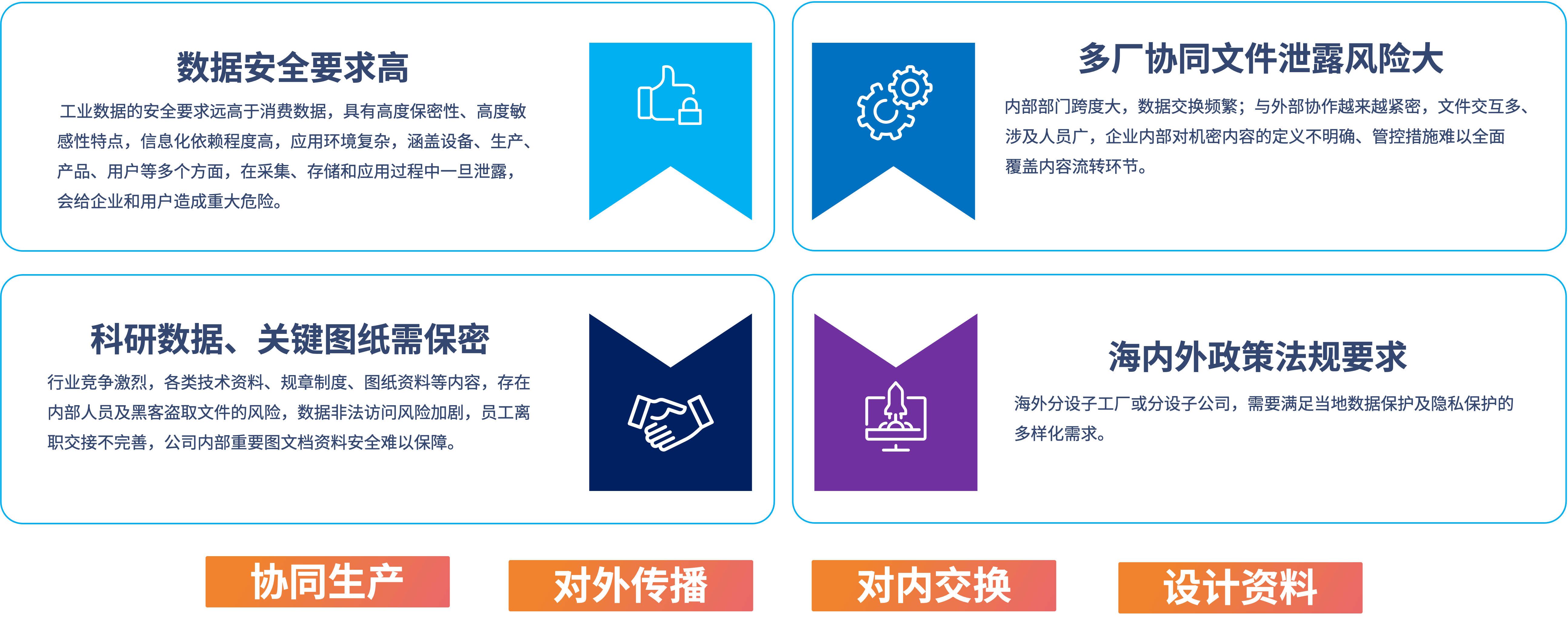

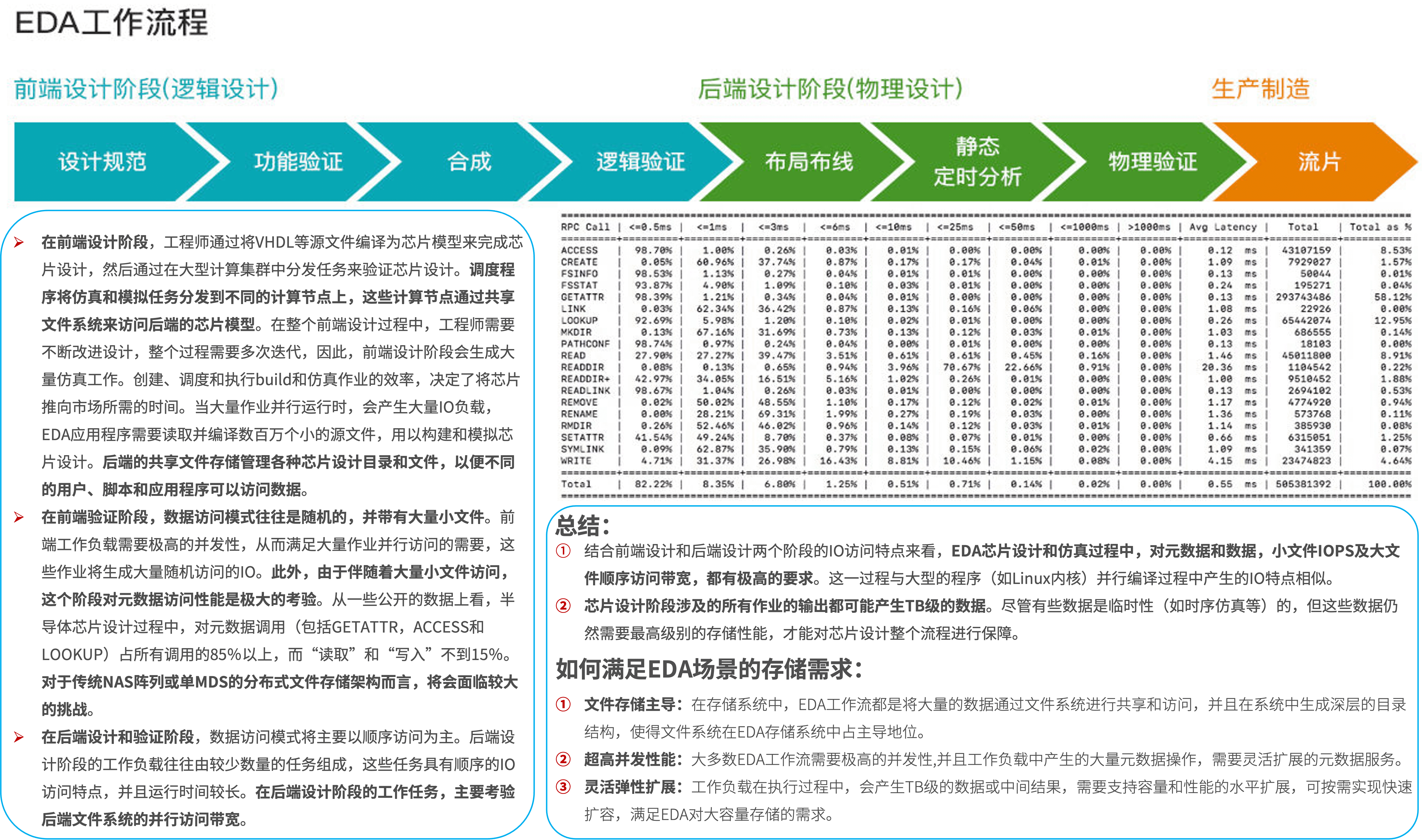

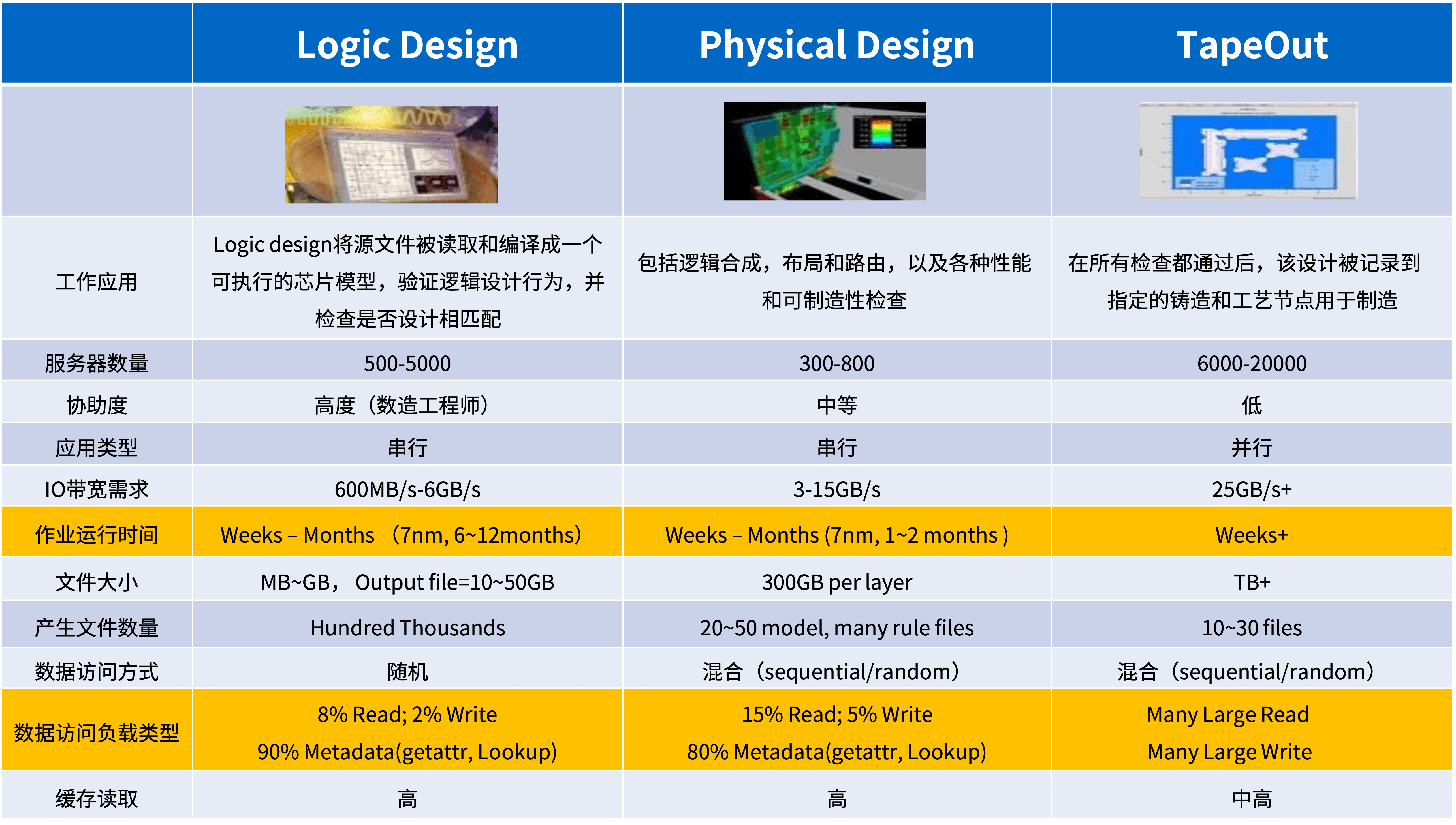

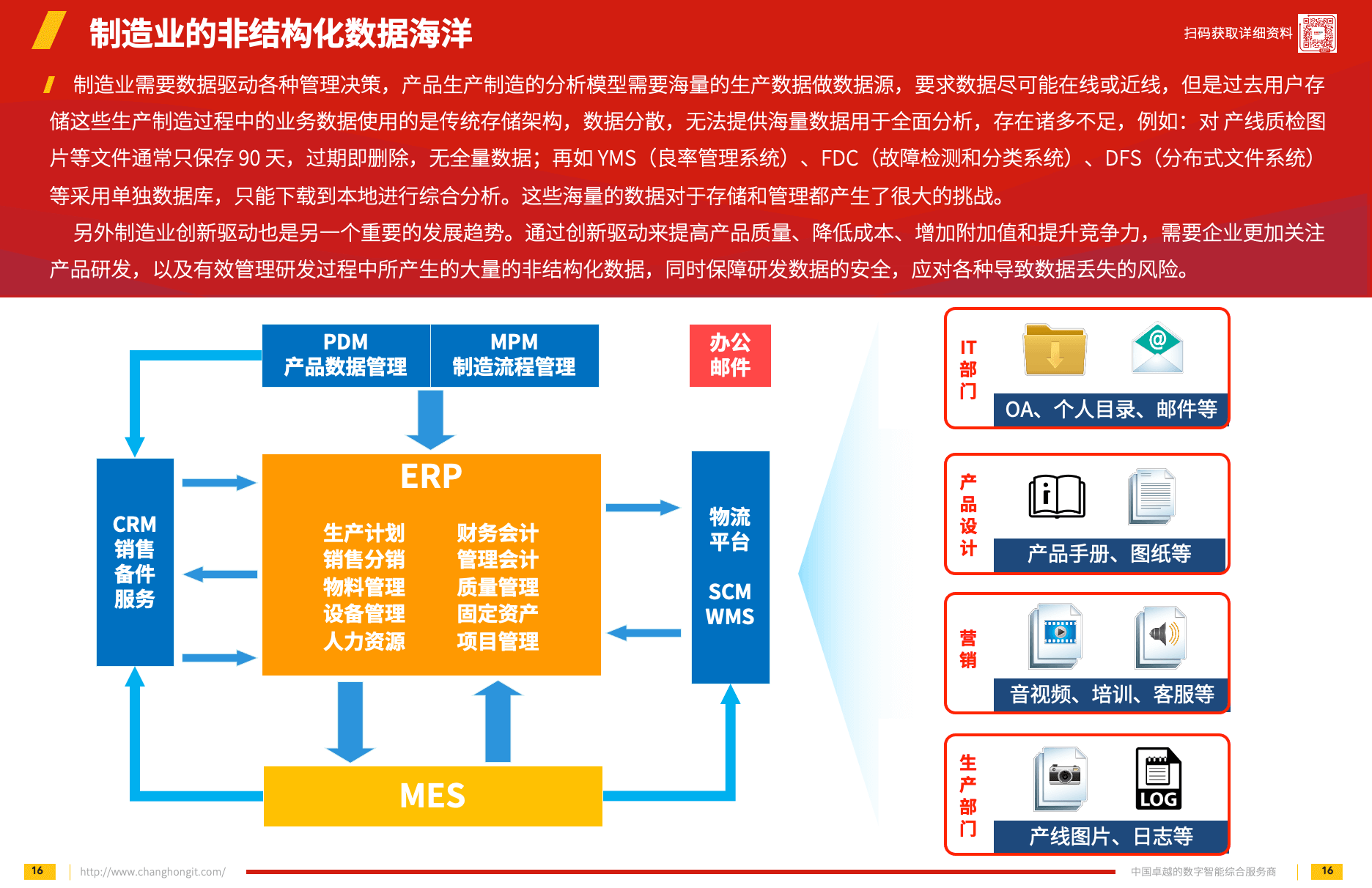

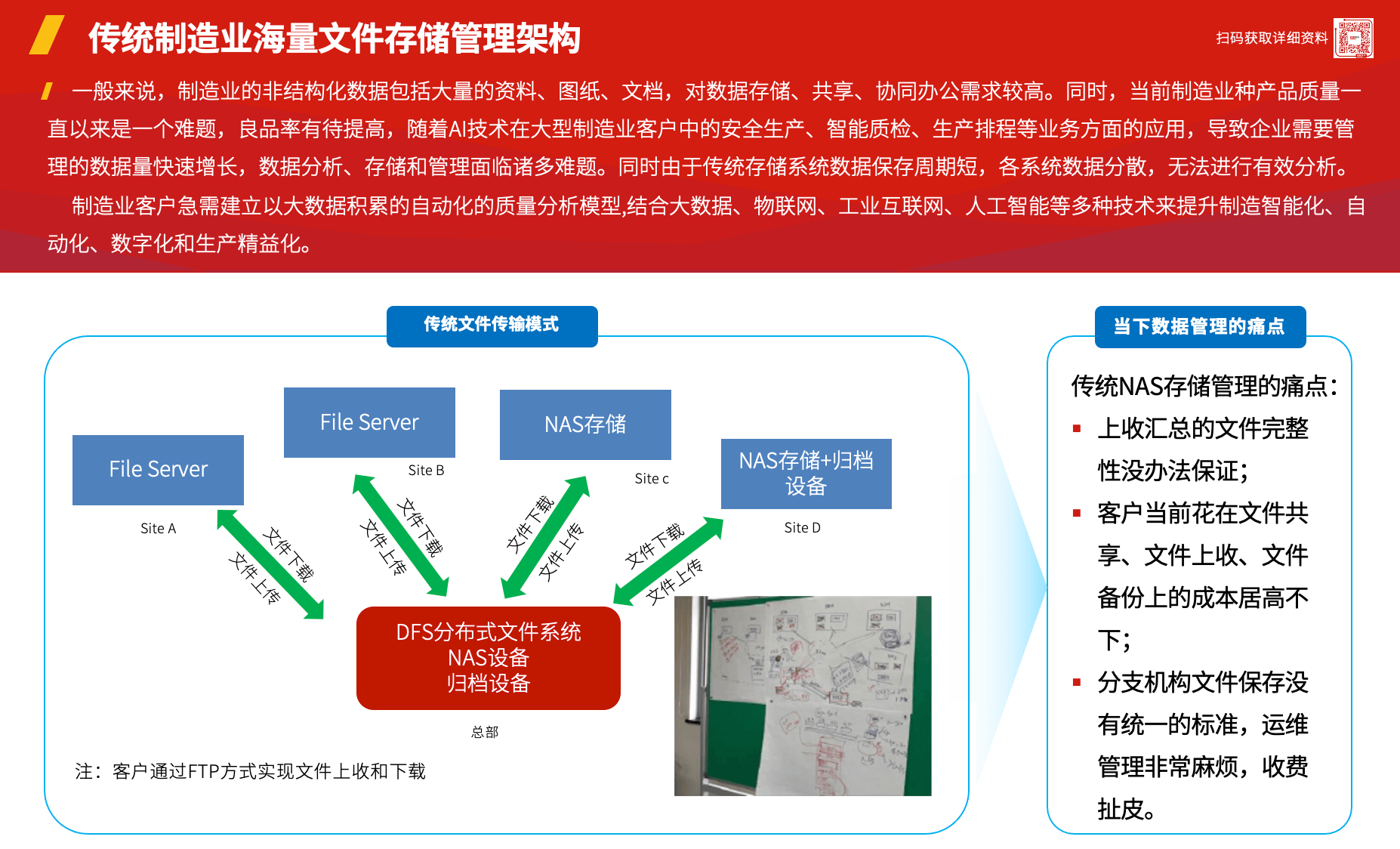

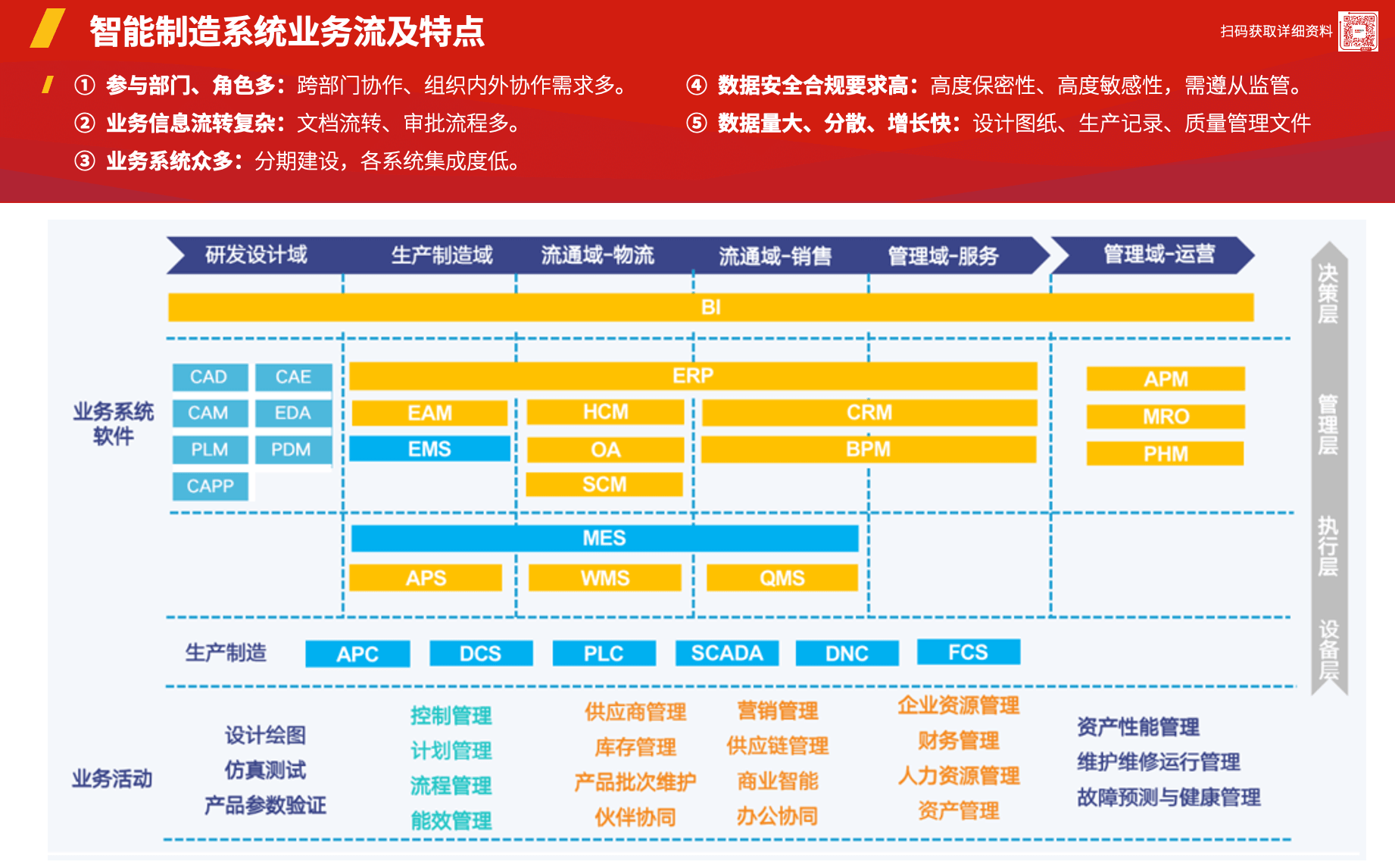

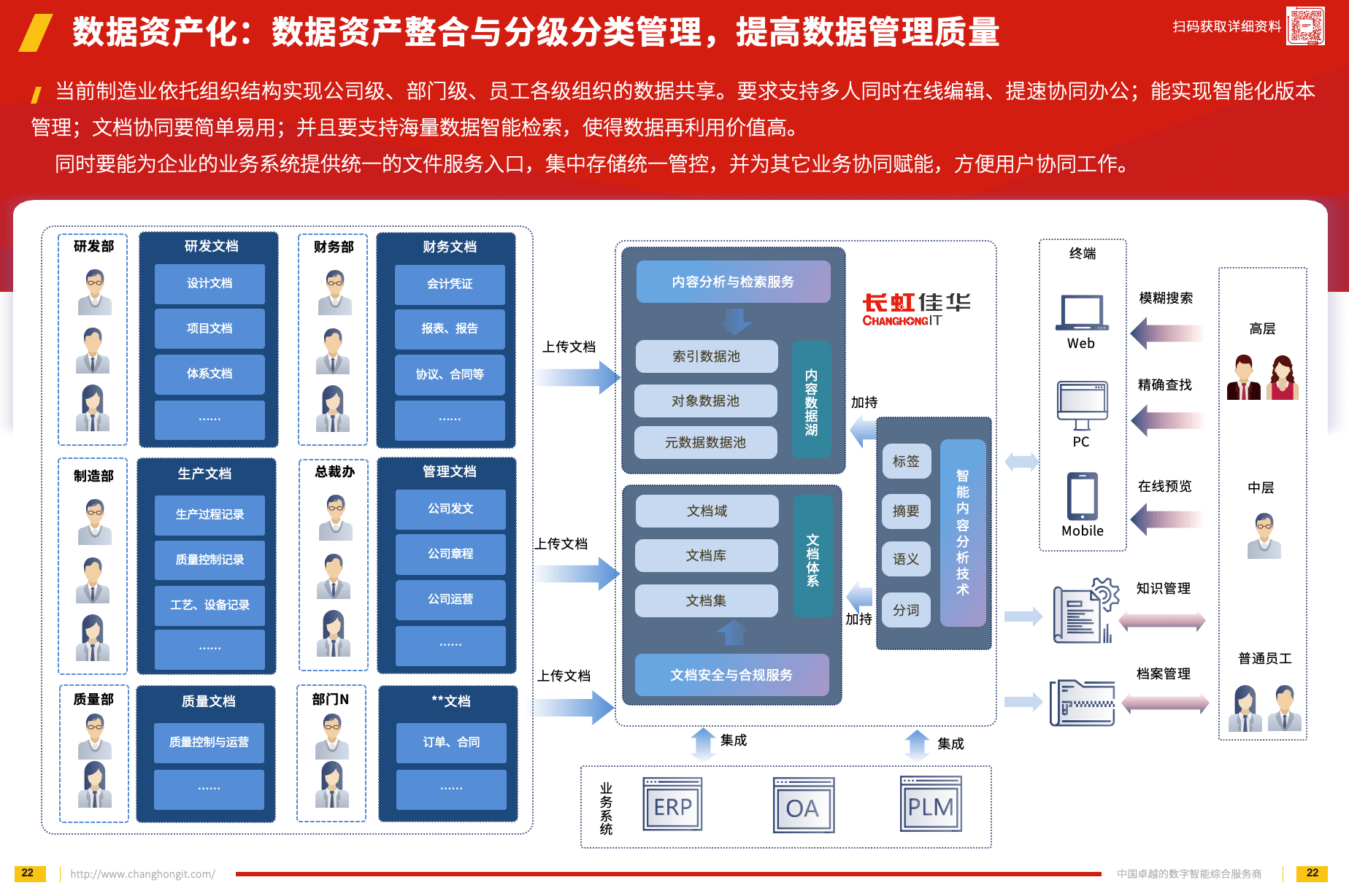

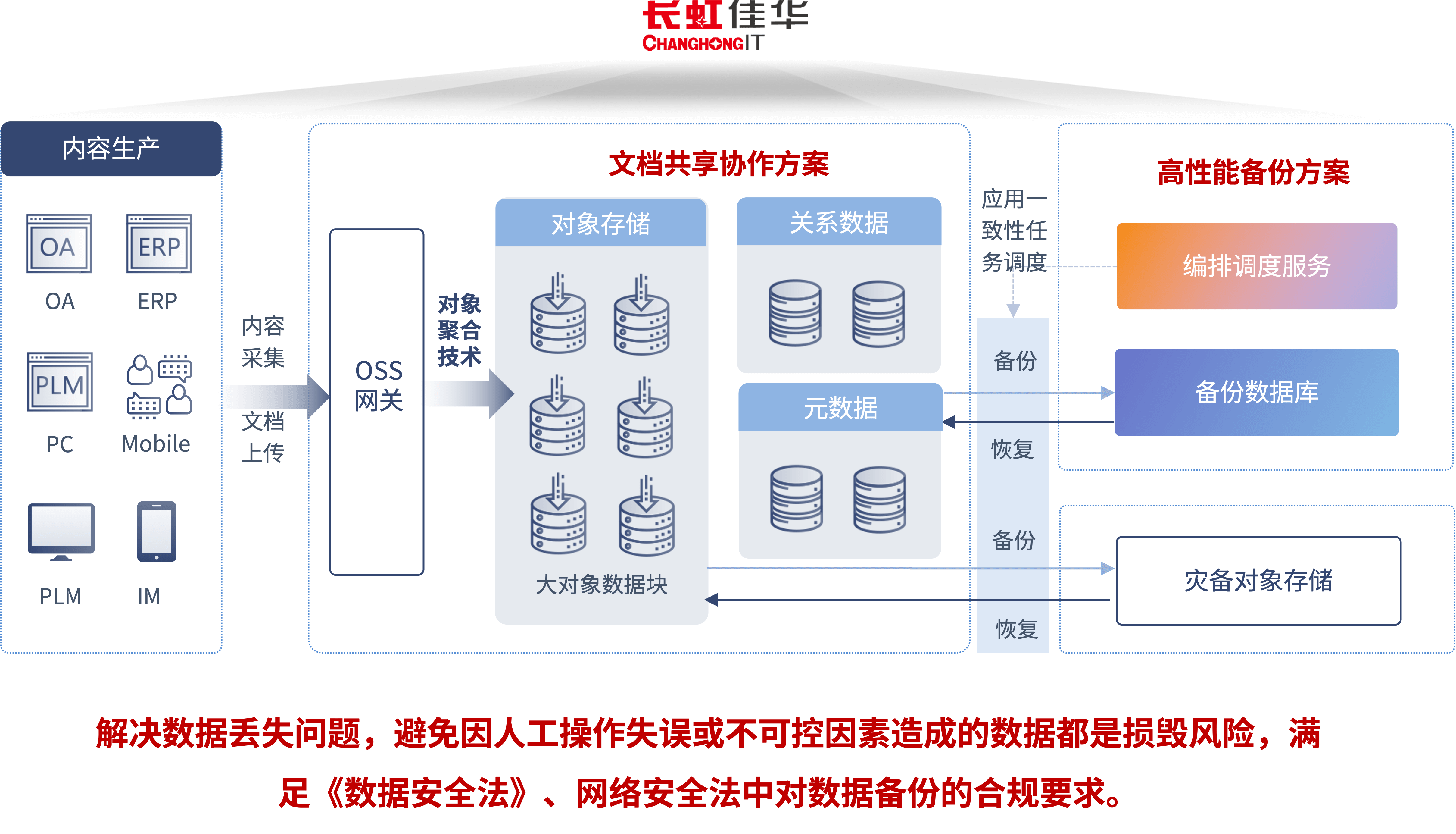

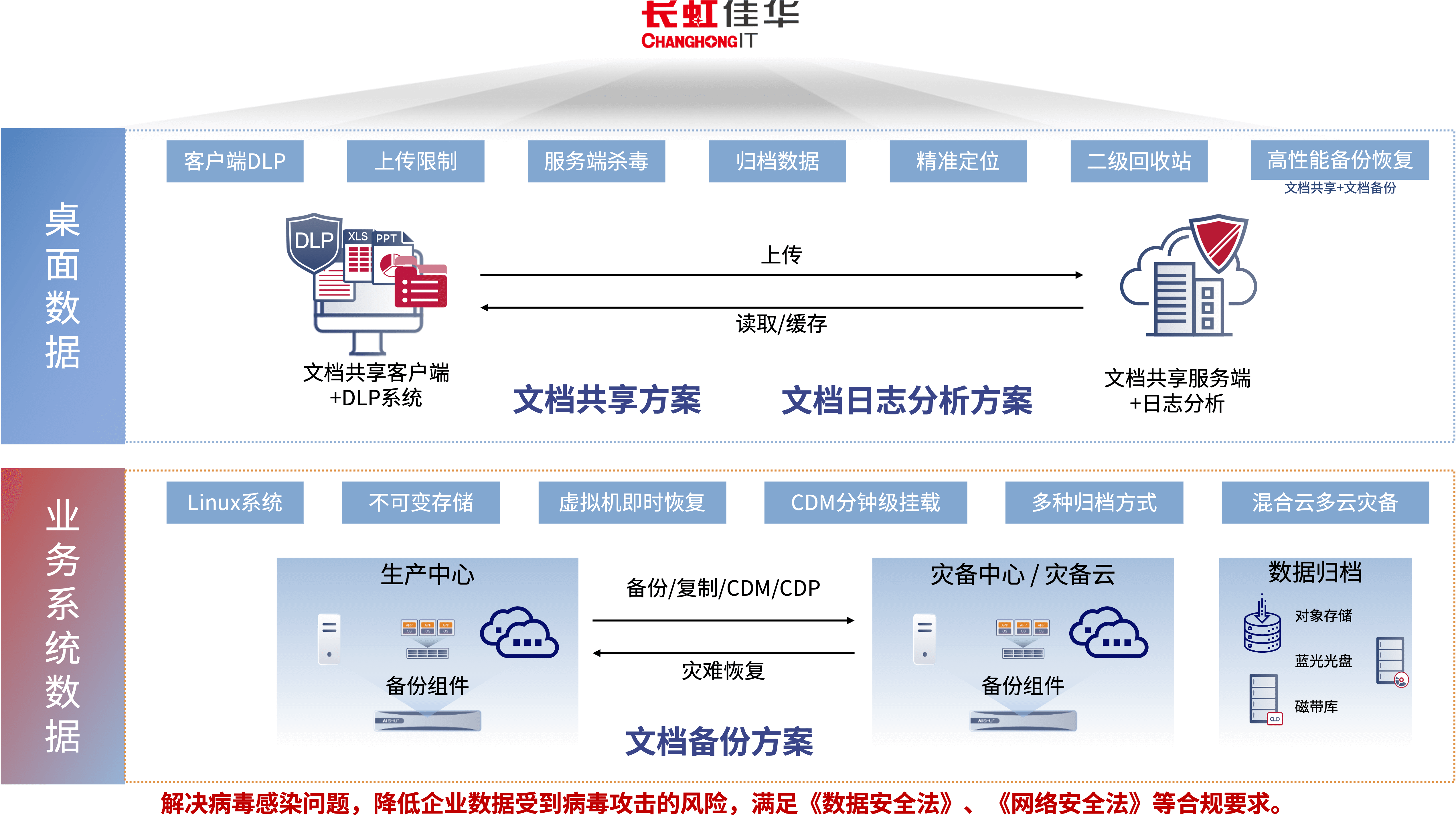

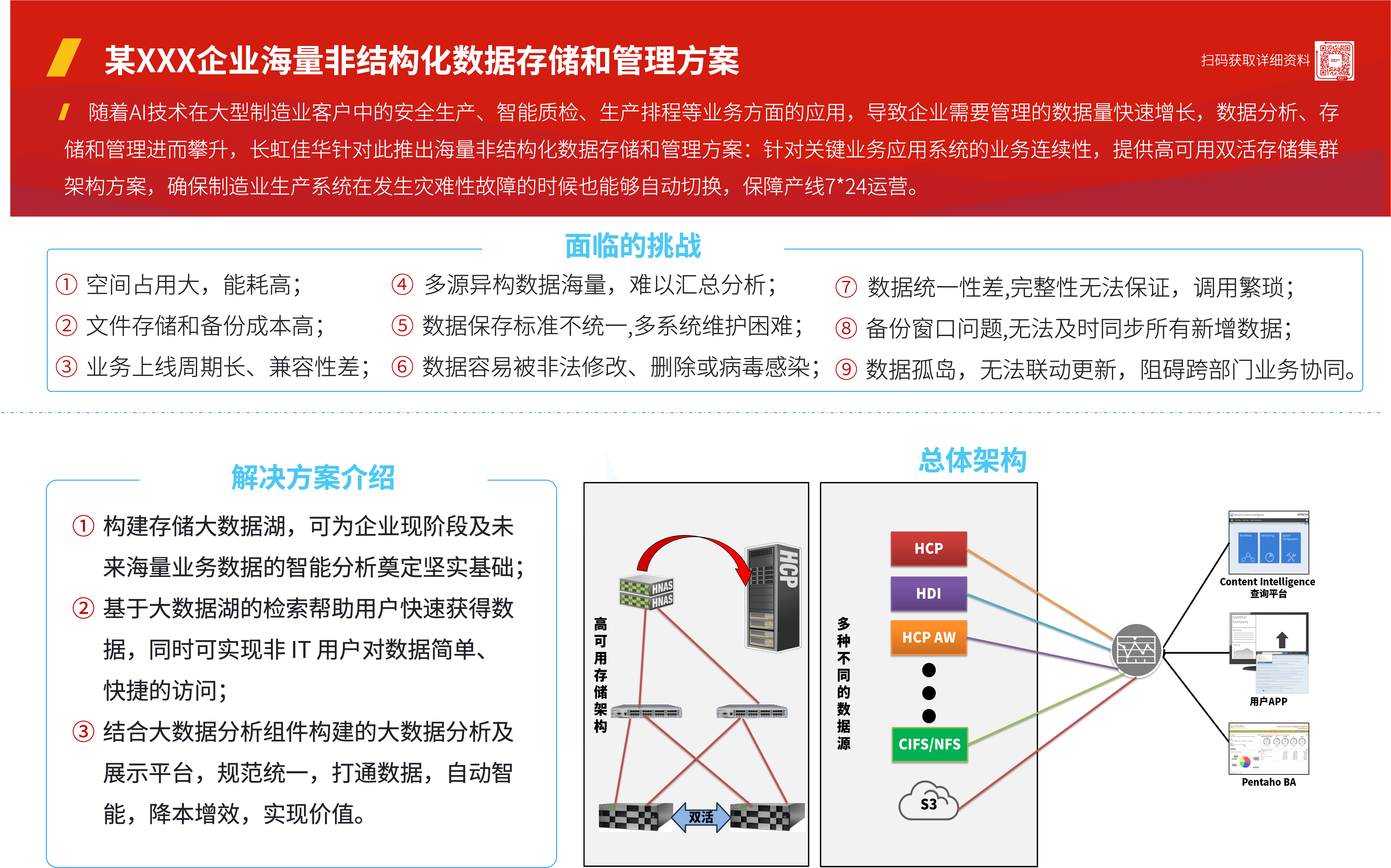

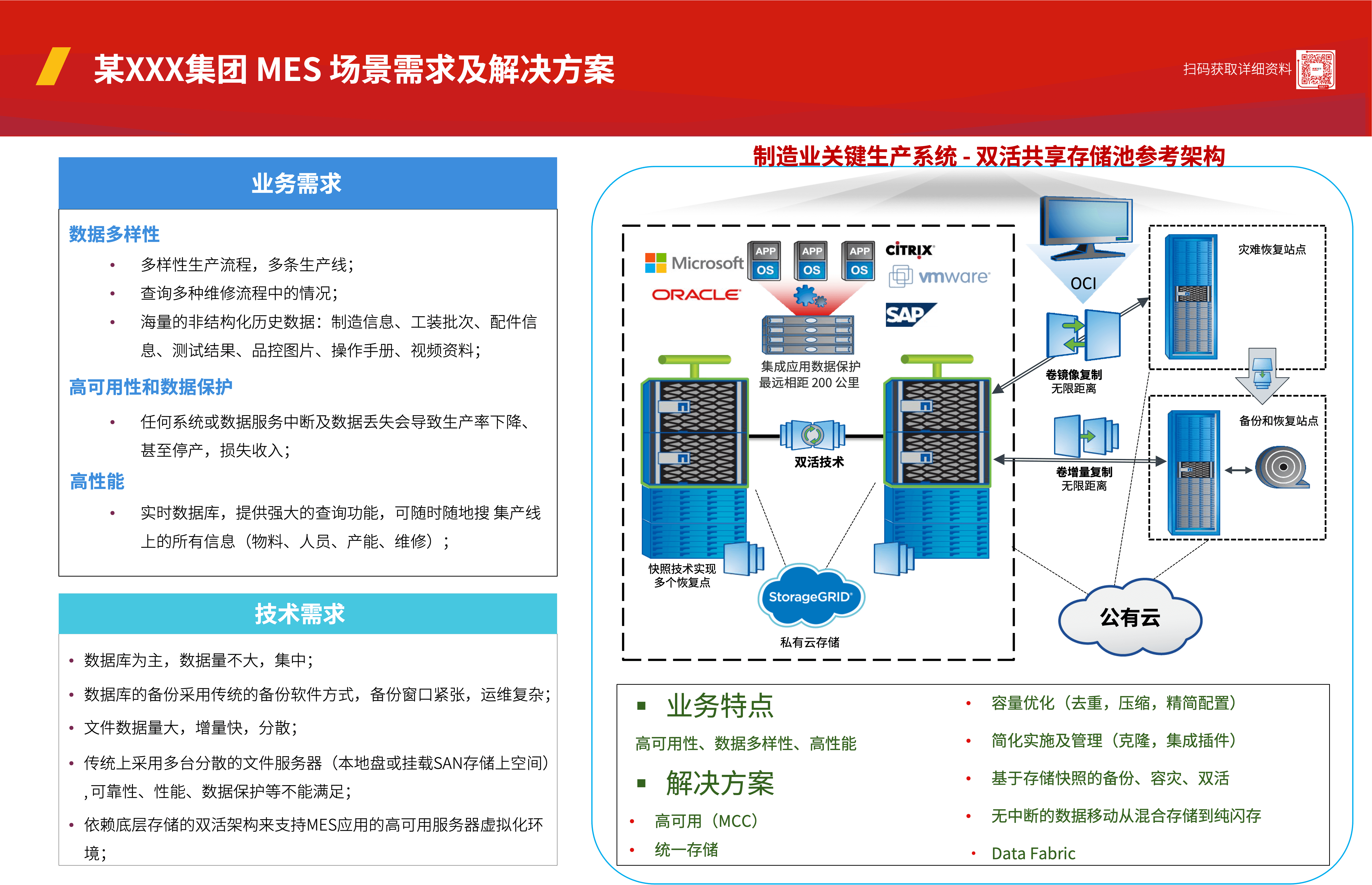

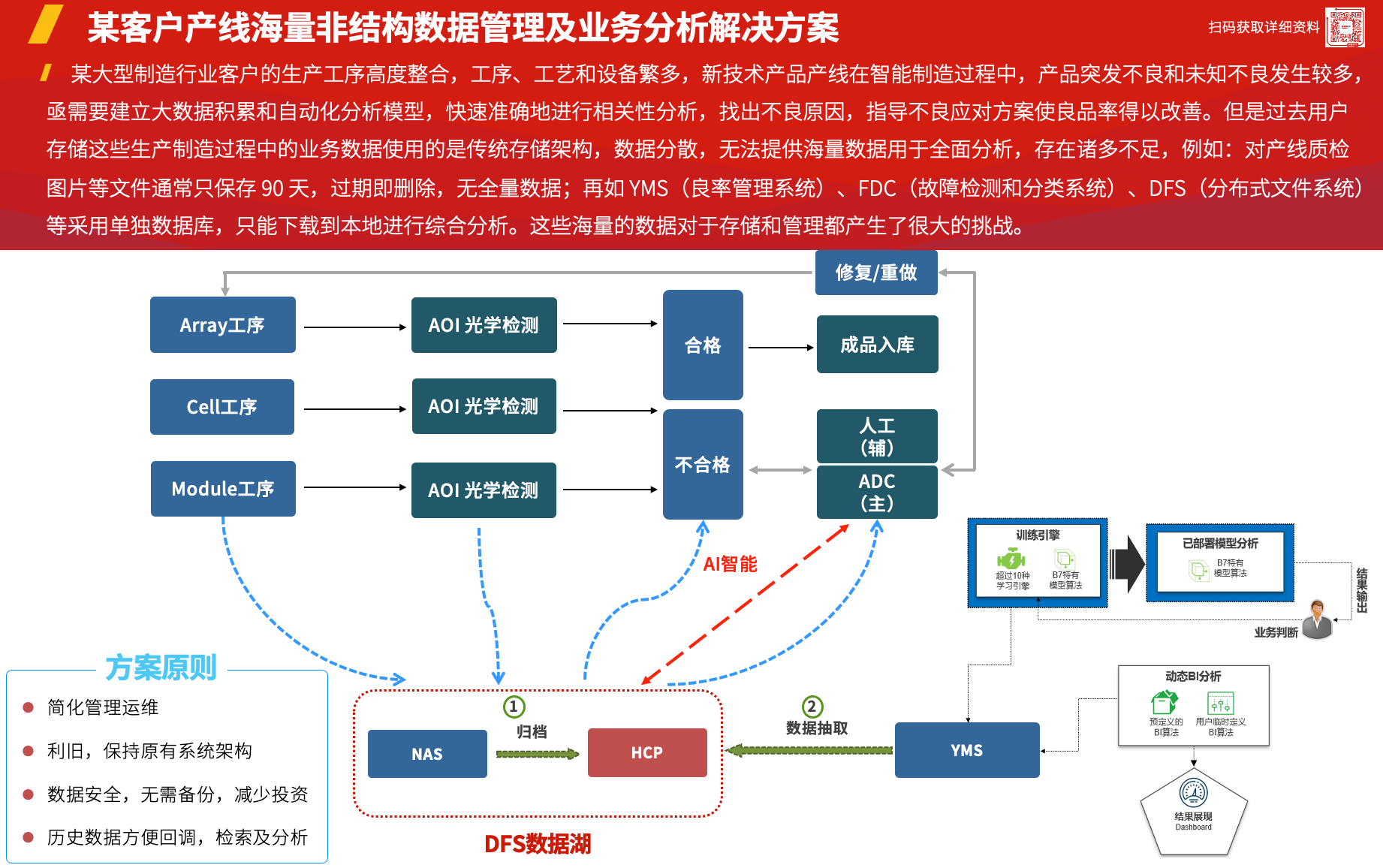

? The manufacturing industry needs data to drive various management decisions, and the analysis model of product manufacturing requires massive production data as a data source, requiring data to be online or near the line as much as possible. However, in the past, users stored business data in the manufacturing process using traditional storage architecture, data dispersion, unable to provide massive data for comprehensive analysis, there are many shortcomings, such as: Production line quality inspection pictures and other files are usually only saved for 90 days, and are deleted after expiration, without full data; Another example is YMS (yield management system), FDC (fault detection and classification system), DFS (distributed file system) and other use a separate database, which can only be downloaded to the local for comprehensive analysis. These massive amounts of data create great challenges for storage and management.

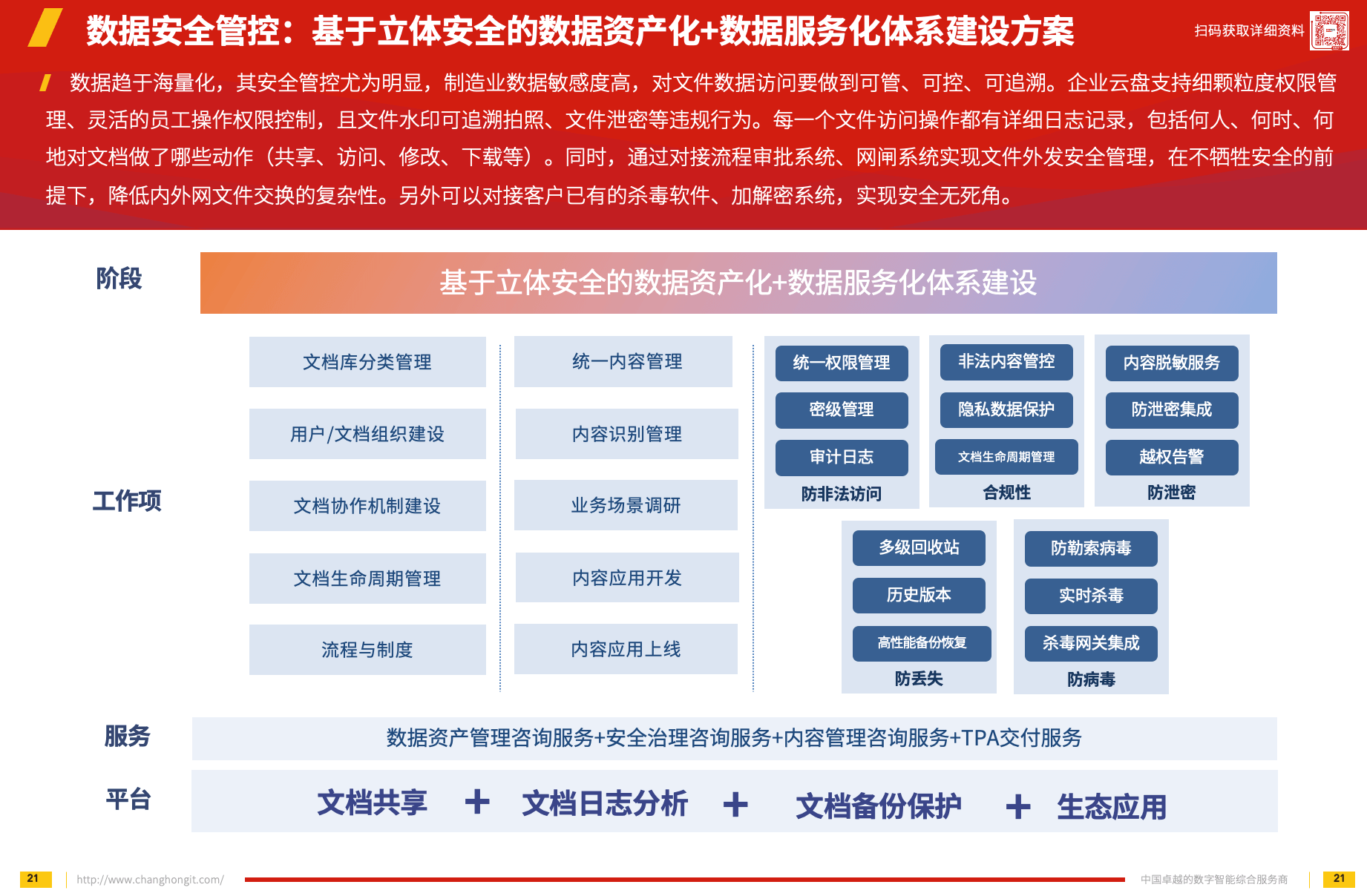

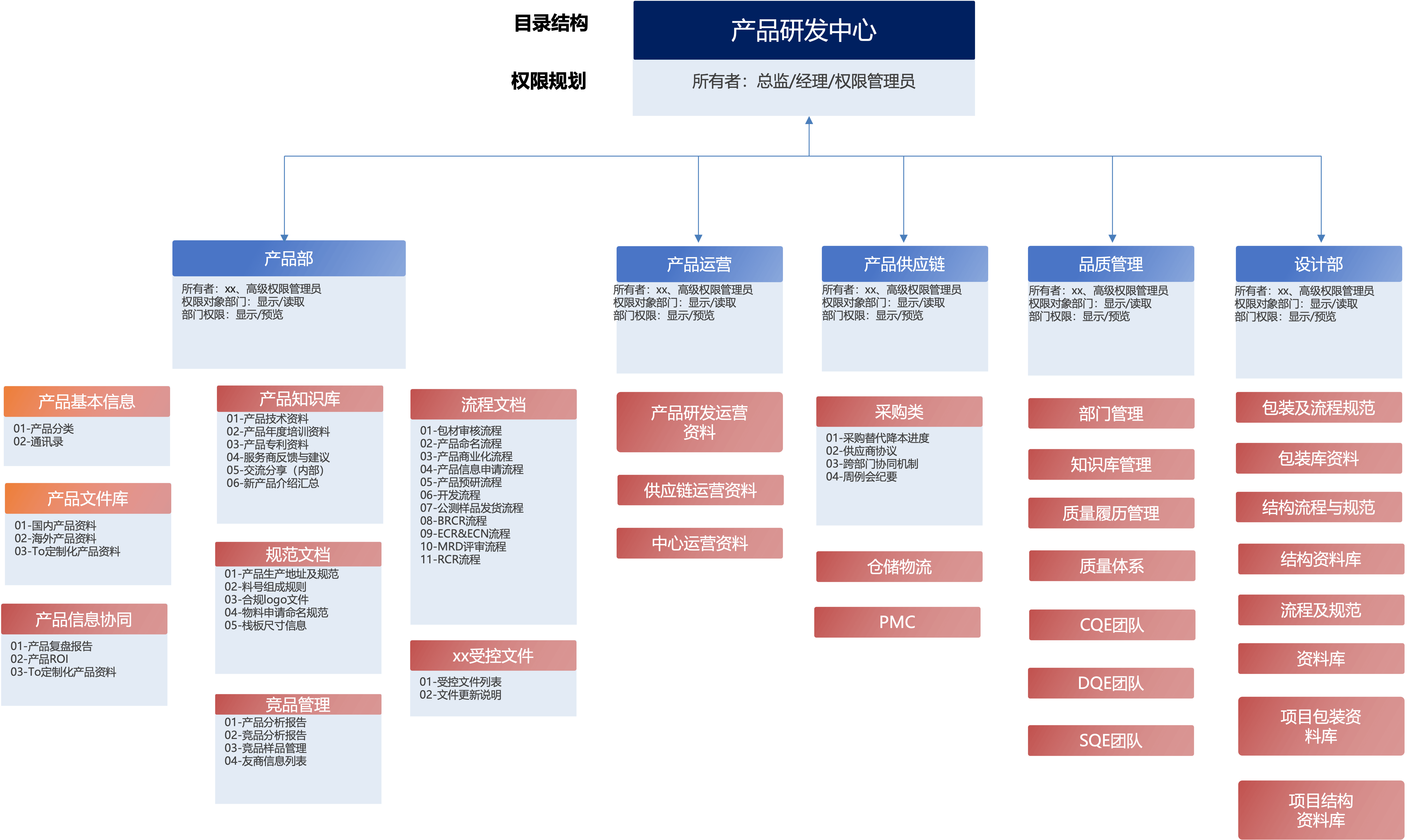

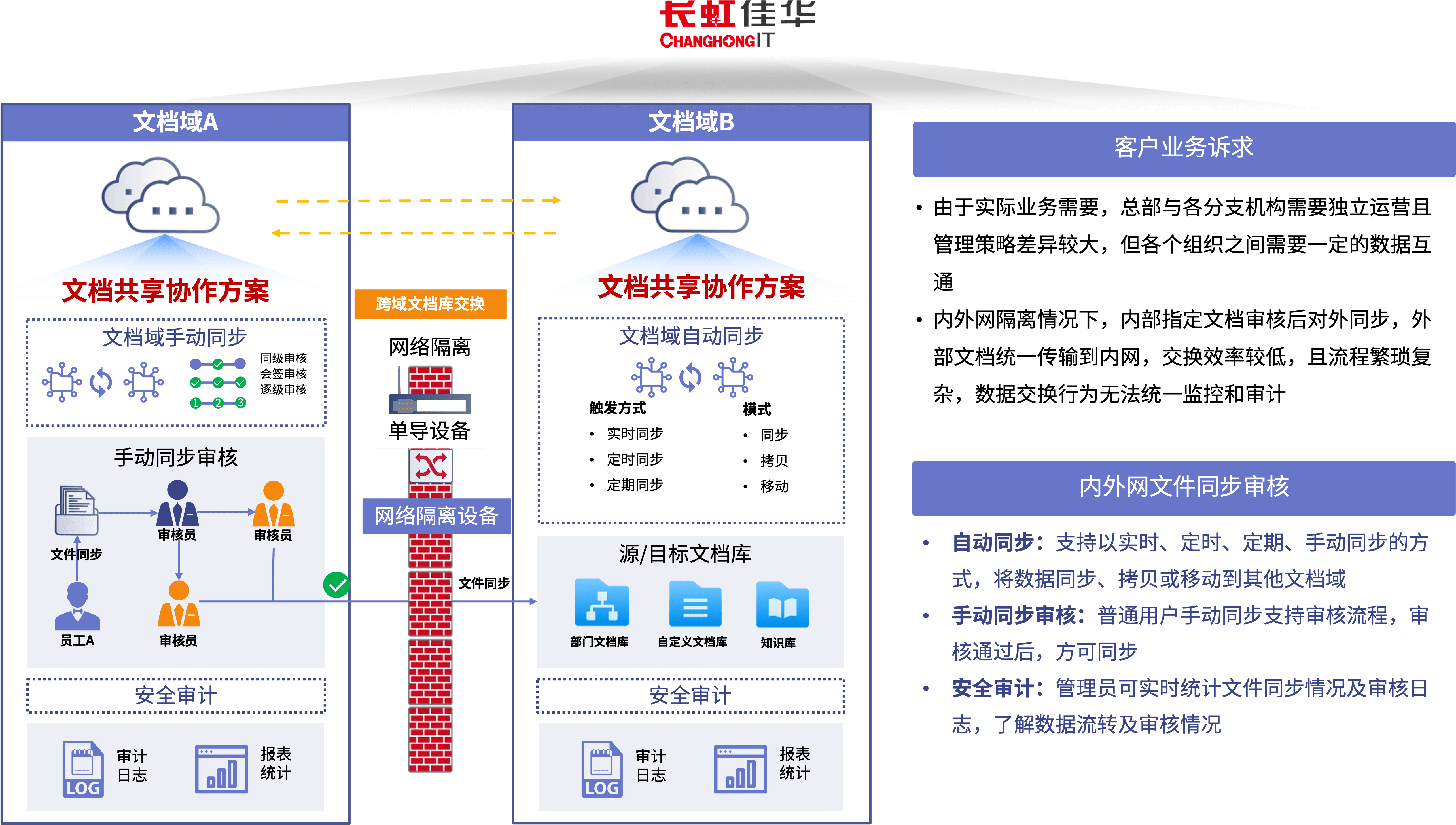

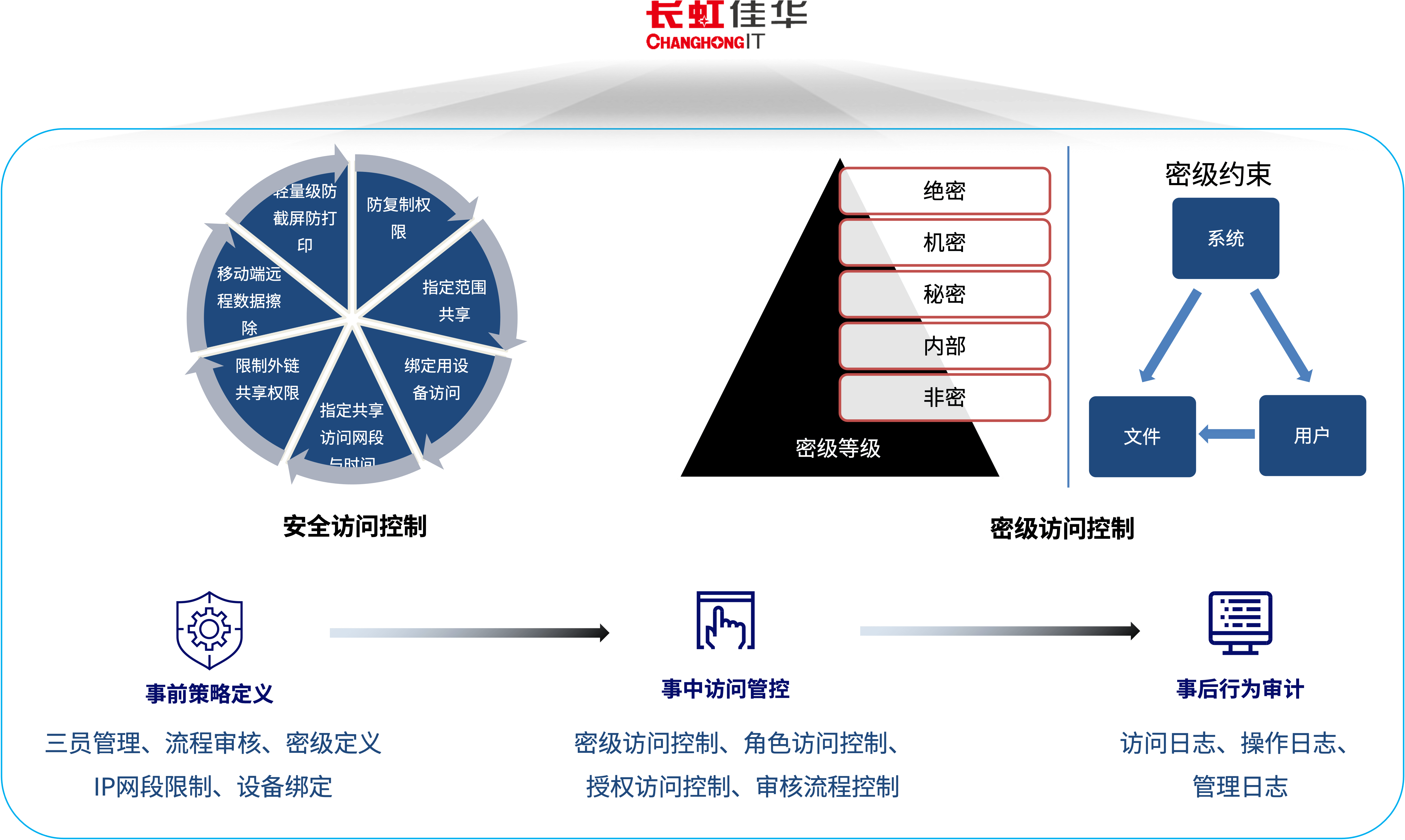

In addition, manufacturing innovation drive is another important development trend. To improve product quality, reduce costs, increase added value and enhance competitiveness through innovation, enterprises need to pay more attention to product research and development, and effectively manage the large amount of unstructured data generated in the process of research and development, while ensuring the security of research and development data, and dealing with various risks that lead to data loss.

Search

Search

Back

Back